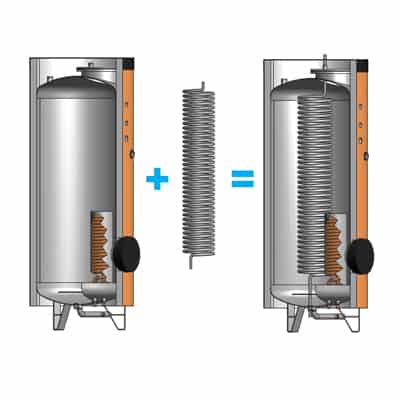

The structure of the energy storage tank is very straightforward: Taking our well established standard DK-Heat Recovery Tank for heating purposes and add to this a premium quality stainless steel spiral tube heat exchanger. The heating water in a raw heating tank is heated with either internal or external single-walled heat exchangers. The drinking water fl ows through the spiral tube. Twin wall heat exchangers are fi tted as standard: to comply with European EN 1717 to protect drinking water.

To heat the drinking water DK relies on a spiral tube. The main reason for choosing this type of heat exchanger is that the pressure loss as compared to a corrugated pipe is signifi cantly lower (about 30%).

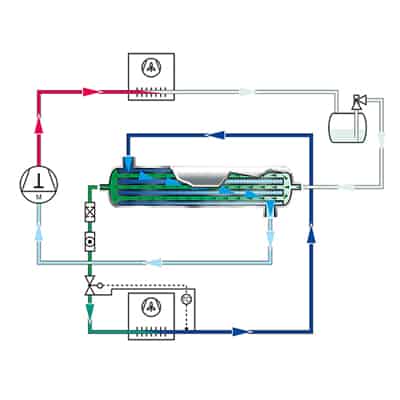

In this system of indirect drinking water heating only small amounts of heated water are stored.

Therefore, a simpler protection against Legionella is provided. Through additional connections for the heating circuit, it is also possible to provide heating power from drinking water to the heating circuit. A primary object of the systems is to achieve the highest possible temperature level at the drinking water exit. Four DK-concepts can offer the Holistic solution.

Using only the waste heat energy from refrigeration systems

The unique concept of this system lies in the unique arrangement of the heat exchangers. The performance of internal heat exchanger of the refrigeration system is available across the entire length of the tank. The heating water return is located in the lower part of the tank and the heating fl ow is positioned at two-thirds of the tank height. Thus, the upper third of the tank will not be traversed by the heating circle and may be heated from the refrigeration units using the de-superheating capacity to achieve a higher level of water temperature. Employing this method and construction it is possible, even at moderate condensing temperatures, to ensure heating water heating in the low temperature range and drinking water heating in the high temperature range.

The waste heat from the refrigeration system is, is the prime energy source for heating the heating and drinking water.

DK systems for serving applications that require higher water temperatures can be offered complete with a factory fitted electric heater, complete with safety over heat proyection control. This system is ideal for smaller projects, such as the Petrol Station

In addition, drinking for the snack bar is simultaneously heated in a continuous process with a stainless steel spiral tube heat

exchanger.

For larger scale projects and heating systems requiring higher fl ow temperatures. DK offer internal or external heat exchangers to provide the complete heating requirement to the upper third of the DK Heat Store Tank tank with a heat pump heat exchanger and/or Gas/LPG/Oil fi red boiler systems.

The core heat source of the tank is the responsible use of waste heat energy from refrigeration plant & equipment – in this case by internal heat exchangers. The benefi ts of heating with internal heat exchangers as opposed to external heat exchangers can be seen in the fact that no additional pumps are needed.

This reduces the investment as well as operating & maintenance costs. The internal heat exchanger offers unparalleled direct and continuous heat transfer performance at all periods of refrigeration plant operation

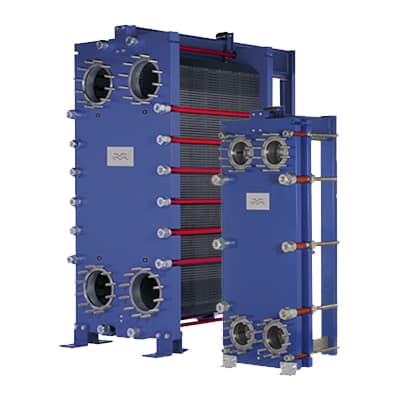

An alternative method to the above previous described system, is the employment of the DK externally (to the tank) heat exchanger. This method is usually required for large pressure lines, and also offers the opportunity to install heat and flow rate metering between the heat exchanger and tank – giving delivery of true and real-time data of performance and efficiency of waste heat utilization & carbon reduction/savings.

In addition, this system allows for easy separation of responsibilities between the various refrigeration and plumbing contractors. This separation and clarity often proves benefi cial for supermarket projects – clearly defining the work responsibilities between the client, main contractor and the specialist installers.