AB TEHNIC Professional

We can help you reduce costs and make savings

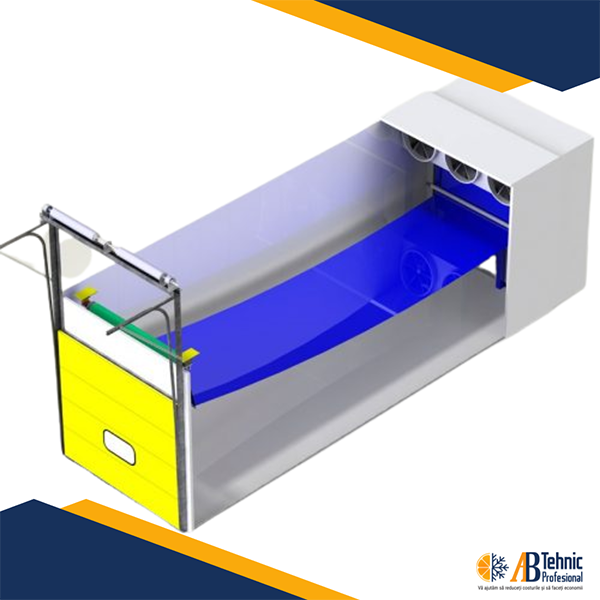

Solutions for the large-scale industrial and commercial refrigeration sector

AB Tehnic Profesional has more than 20 years of experience on HVAC and Refrigeration Market. The experience of our specialists help us to deliver the most effective technical solutions.

Best Prices

Delivery

Secure

Experience

Online shop

SERVICE EQUIPMENT

CATEGORY 2

CATEGORY 3

Product categories

Do you need consultancy?

Since 2002 Frigo Consult Tehnic AB represents an autonomous consultancy company in refrigeration technology. Frigo Consult Tehnic AB offers refrigeration systems design and various spare parts distribution. Its team strives for continuous growth and great accomplishments in the refrigeration and air-conditioning industry

ADDRESS:

Str. Alunisului Nr. 164, Sector 4 Bucuresti

office@abtehnic.ro

PHONE NUMBERS:

021 332 08 48