The RFF Ball valves have been designed for refrigeration installations using ammonia, CFC, HCFC, HFC or halocarbon refrigerants.

Temperature range from -50°C up to +150°C. Nominal pressure rating is 25 bar.

Valve flange connections are available to the following:

- Butt welding Class "S" (ASTM Pipe Schedule "standard")

- Butt welding Class "M" (DIN 2448)

- Brazing Class "B" (ANSI B.16.22)

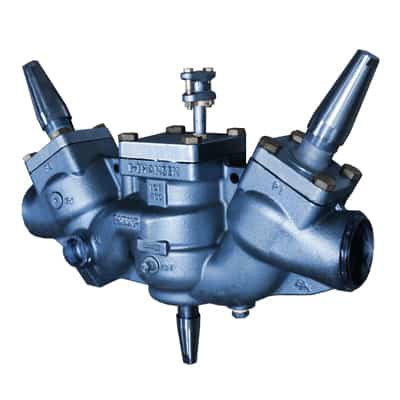

Designed with full bore flow, the RFF Ball valve has low pressure drop with high Cv values.

The valve body, subjected to pressure, is manufactured from low temperature impact tested steel. The valves can be supplied with material certificates to EN 10204.3.1.B. when specified on order.

The simple three piece body design is easy to install without the need for special torque tools. Efficient Insulation is possible due to extended valve head.

The lower end of the valve spindle is sealed tight by a PTFE seat held in place by a compressed spring.

This allow the replacement of the spindle "O" ring while the plant is on line..

The top spindle seal incorporates the proven standard RFF design using two "O" rings with a lubricating, non freezing oil, reservoir between them.

The Ball seat seal gas tightness is obtained by two special fibre glass reinforced PTFE rings.

A vent hole is drilled in the ball to avoid trapped liquid and possible damage by hydraulic expansion when the valve is closed.

The vent hole is situated on the upstream side of the ball. The valve has only one direction of flow.

The valve has two spindle seals, one under the spindle thread and one above the spindle thread.

If the flats of the stem are parallel to the piping, the valve is open. If they are perpendicular, the valve is closed.

The Ball valve can be supplied with a seal cap fitted with a rubber "O" ring. There is an internal groove for venting gas to ensure safe removal at atmospheric pressure.

For installations with others refrigerants, including ammonia, a lever is available for opening and closing..

Instead of the cap, a lever can be supplied when leaks are less critical (eg. For ammonia)

If the valve needs to be automatically actuated, it can be supplied with an ISO flange.

Then any ISO actuator can be fitted.

- Pneumatic actuator can also be supplied. This is spring return actuator so that valves shut off automatically in case of power supply fault.

- Temperature : - 20°C / + 85°C(This actuator use dry air where dew point is about 10°C less than minimum temperature - Air pressure : 5 to 10 bar)