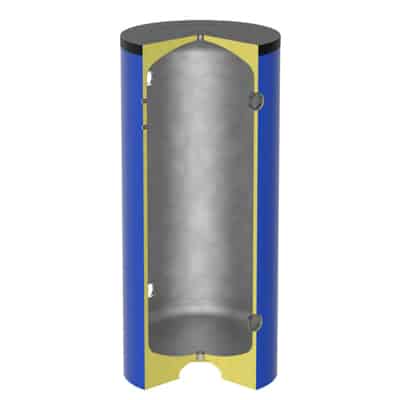

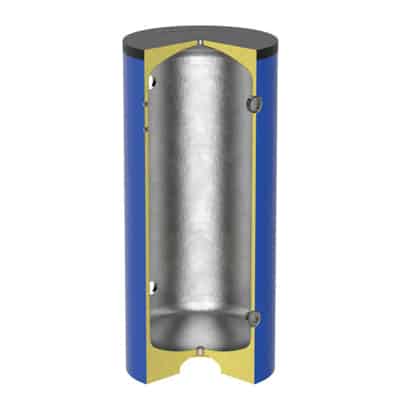

VKG buffer tanks are insulated to only contain chilled water. They are generally used in conditioning systems in which there is not a particularly high need for protection against corrosion. VKG buffer tanks have the job of increasing the system’s thermal inertia and are recommended for single loop or double loop applications. They are available, depending on their capacity, in a vertical and a horizontal version. The exterior coating can be in PVC for indoor installations (VKG) or in embossed aluminium for outdoor installations (VKGE).

- Capacity range From 100 to 10000 Litres

- Material Carbon steel S 235 JR

- Insulation PU-R/PE

- Coating PVC/Embossed aluminium

- Operational limits -10°C + 60°C/6 bar

- Usage Hydronic conditioning

Buffer tanks are tanks used to store chilled water, allowing the operating cycle of the matched heat pump to be optimised and thereby increasing its efficiency. Fiorini buffer tanks stand out in terms of their longevity, the high-density insulation used and the finishing done in true “Made in Italy” style. The range of Fiorini buffer tanks has been designed to improve the operation and the performance of the most advanced conditioning systems. The broad range and the options for customisation enable optimum solutions to be built for any type of system. Fiorini buffer tanks increase the system’s water capacity and improve the longevity of machines, heat pumps, chillers and compressors.

- Reduced machine wear

- Stored heat energy

- Optimised operating cycles

- Customised solutions

- Fewer compressor start-ups

- Heat pumps operate at full capacity

Fiorini buffer tanks are used to store chilled water and are essential in every conditioning system that operates with a reduced amount of water. Installing a storage tank makes the heat pump more efficient and increases its longevity.

Thanks to the storage of chilled water, provided by Fiorini buffer tanks, continuous and rapid changes in the water temperature, due to intermittent regulation, are avoided. Installing a Fiorini buffer tank is also recommended because it reduces, as far as is possible, the compressor’s start-up and switch off cycles.

The storage tanks, depending on the aim, can be divided into balancing tanks and in-line storage tanks. The balancing tanks create 2 separate circuits which have anti-mix or internal baffles, diffusing pipes or conveyor pipes. The in-line storage tanks, on the other hand, do not divide the circuit and should be installed on the return side, preferably before the circulation pump.